Flying vehicles without a pilot has launched things like package delivery, surveillance, military operations, and even filmmaking into the future. And looking to the future also means thinking of the environment. That’s why a team of four undergraduate students from Louisiana Tech University have created a prototype of a drone made of 70% environmentally friendly materials.

In a study recently published in the Journal of Unmanned Vehicle Systems, the team describes how unmanned aerial vehicles (UAVs) that crash or get lost in remote areas can have negative impacts on the environment.

“Given the rising usage of UAVs, having these items be recyclable reduces their environmental impact as opposed to single-use materials,” said Arden Moore, a mechanical engineering professor at Louisiana Tech University and the group’s supervisor. Generally made from plastics, metals, and other non-biodegradable materials, UAVs or drones can pollute environments if they “were to crash in an inaccessible or protected area,” said Moore.

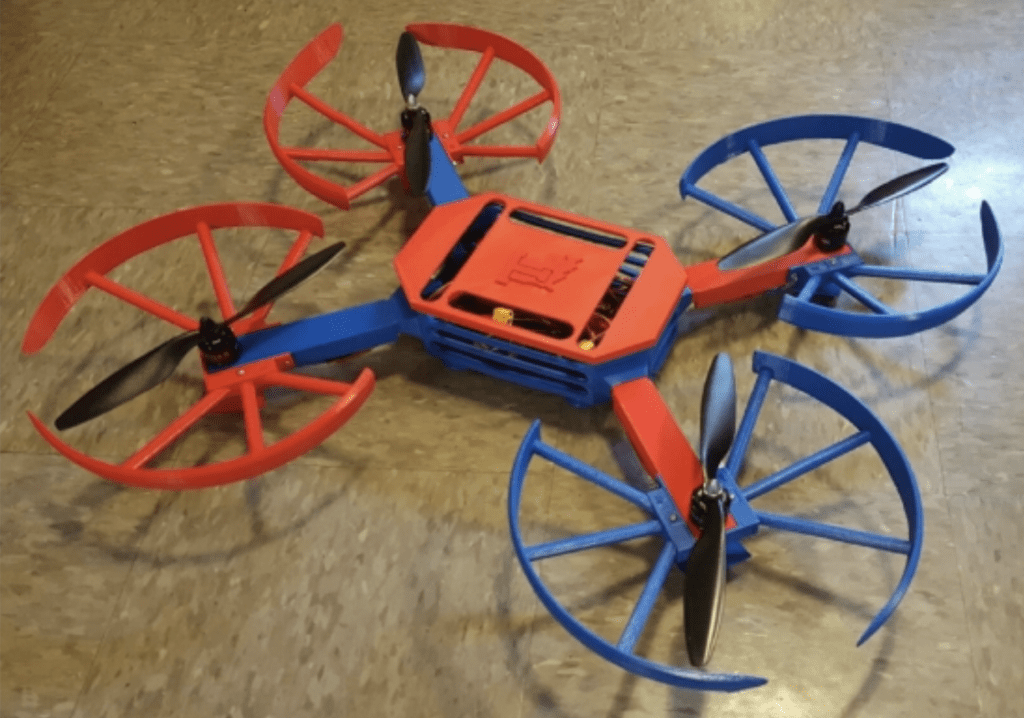

Moore tasked the undergraduate engineers to develop a UAV that could fly 30 m high at a speed of 9 km/h, carry 100 g of payload, and fly for at least one hour. This needed to be achieved using unconventional, eco-friendly materials. The resulting drone met or exceeded all the requirements, except flight time, which likely could have been achieved with a more powerful battery.

“Biodegradable materials are typically sensitive to moisture and heat…this means that you must choose your material carefully for the operating environment so as not to have your components break down too quickly while still in use,” said Moore. The team looked at wood, fibreboard, and plant-based bioplastics and in the end chose a plant-based bioplastic that is both recyclable and bio-degradable.

The deciding factor for choosing the eco-friendly bioplastic was the ability to use 3-D printing—another up-and-coming technology. The team designed pieces of their UAV on a computer then sent their design to the 3-D printer that built the pieces with their selected material.

“The 3-D printing aspects of this project really gave the team flexibility in terms of the types of shapes and structures they could consider,” said Moore. It allowed the team to try numerous forms of their UAV and iterate a design quickly without having to rely on molds.

A prototype of the 3-D printed drone (Photo | Arden Moore)

In real-world applications, the 3-D printed drone would also allow for quick repairs in remote locations. “In these cases, a user could simply 3-D print a replacement part and get flying again,” said Moore.

The final UAV that the team of engineers constructed was a quadcopter. The frame was made from 3-D printed bioplastics while the motor, batteries, propellers and remote controls were purchased “off the shelf” and were not made from sustainable materials.

Future work would look at strengthening some of the components made from bioplastics to minimize breakage during rough landings.

Although there are still parts of the UAV that cannot be constructed of sustainable materials, the team from Louisiana Tech University showed that progress is being made and eco-friendly machines have a future.

Read the full study: A low-altitude unmanned aerial vehicle (UAV) created using 3D-printed bioplastic in the Journal of Unmanned Vehicle Systems.