It is one of the most difficult and dangerous jobs in Canada.

Clouds of breath-robbing particulates, the risk of falling rock, and even radiation encircle the work. It is often solitary, bleak, and confined. It demands great skill, protective gear, precision, and care, and the lives and livelihoods of many as well as a critical Canadian resource depend upon it.

This is the job of shotcrete operators, the people who run spray concrete equipment in underground uranium mines. They apply sprayable concrete to the mine ceiling and walls to stabilize them for the safe movement of equipment, materials, and people.

The task begs automation, and the quest to create a truly independent system that can function in all circumstance has engaged robotics researchers for decades.

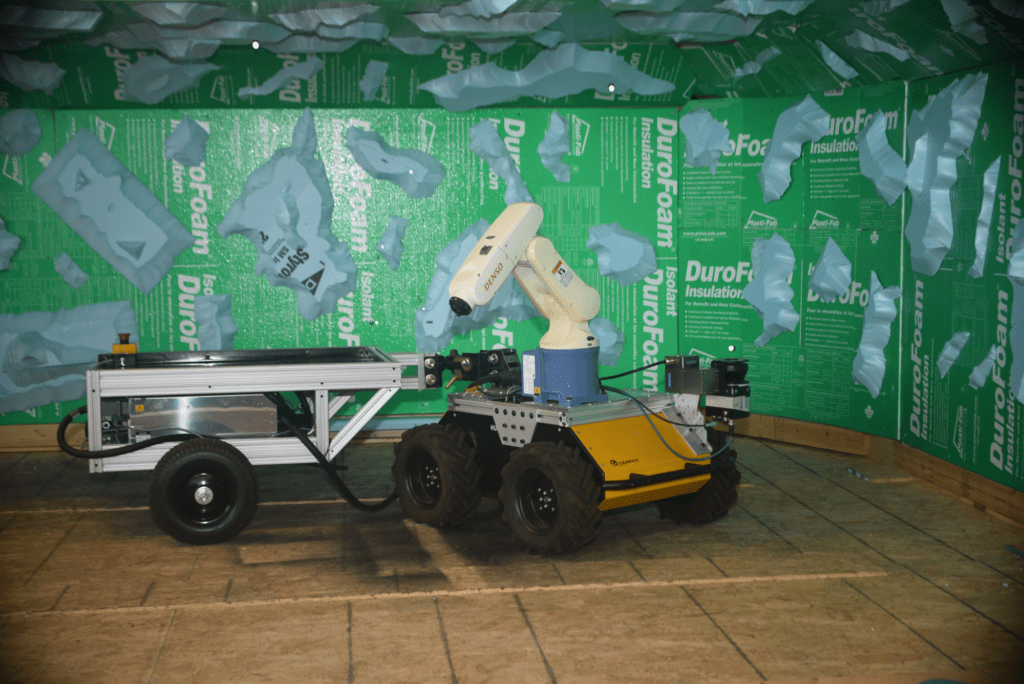

Now, a team at Ontario Tech University (OTU) in Canada has created a fully autonomous robotic system: one capable of entering a mine shaft, scanning irregular wall surfaces, applying shotcrete evenly across the walls, moving along the shaft, and repeating the process with a near seamless application and with a record of before and after scans to verify consistency.

The successful demonstration of the system in a scaled mock-up of a uranium mine tunnel is described in an article published recently in the Transactions of the Canadian Society for Mechanical Engineering.

The project used a combination of advanced sensor technology, a mechanical manipulator, and a mobile robotic platform. The sensor, a LIDAR (Light Detection and Ranging) scanner, gathers data on distance to a myriad of points on the wall surface that are blended to define its 3-D shape and to generate the trajectory that the spraying system should follow to cover.

This process has worked well in the past when applied to a uniform, flat surface or one defined by precision tunnelling machinery. But it has proved imperfect when scanning walls with random combinations of curves, crevices, and plateaus and when the transition from the side walls to the ceiling is unclear. Furthermore, some surfaces cannot be detected from a fixed position.

In addressing these issues, data not only have to inform the direction of the spray nozzle and its movement, but also the distance from the surface, the positioning of the vehicle supporting the robotic arm, and most importantly the path the spray will follow as it seeks to cover the walls consistently.

“This is not trivial,” says Scott Nokleby, co-author of the study and Professor at OTU. “If spots are missed or only receive light treatment, the mine wall is left unsafe and unpredictable, and if too much shotcrete is applied, the material can bounce back causing other problems as well as waste.”

Prototype system and mock-up mine

As none of the standard approaches to guiding trajectory paths could address these issues, OTU graduate student Michael Wrock and Professor Nokleby found their solution in a hybrid algorithm and an innovative integration of software.

The tests of their novel technology were conducted in a 1:3 scale model of a mine tunnel in Northern Saskatchewan. This region holds the world’s largest deposits of high-grade uranium, a material that underpins a major export industry as well as electrical power for millions of Canadians.

The autonomous shotcrete system has major implications for mining, and the next step will be development of an industrial-scale system and testing in an actual mine.

But it is easy to envision many other uses for robotic concrete spraying such as in repairing buildings, supporting bridges, making swimming pools, and other tasks that are not quite as demanding as applying shotcrete in a uranium mine.

Read the paper: Trajectory via point generation for autonomous mobile manipulation using 3-D LiDAR data in the Transactions of the Canadian Society for Mechanical Engineering.

Banner image: Plane intersections | Michael Wrock, Scott Nokleby